Merry CHRISTmas Everyone.

I’m a Texas guy that now lives in Hong Kong. I left my life as I knew it, to start a new life. One filled with unfamiliar sites, languages, foods, smells, culture and people. This “leap of faith” is still leaping, but I’m beginning to see the ground beneath me. If you ever wondered what it would be like to pack your bags, say good bye to everyone you know, jump on a plane to another world- then get ready. Here’s a look at life in Hong Kong… according to Ken.

Wednesday, December 25, 2013

Tuesday, December 24, 2013

Wednesday, December 18, 2013

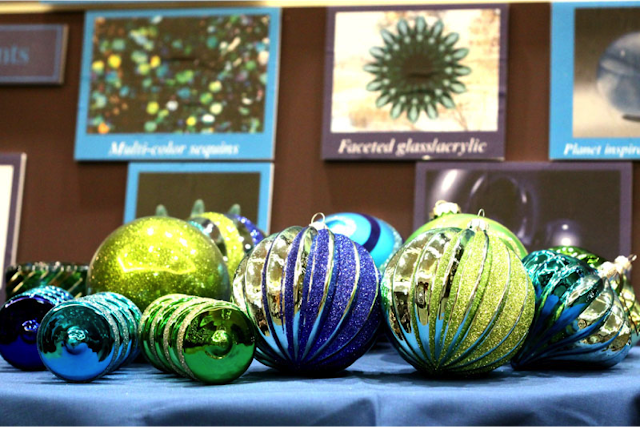

I'll have a Blue Christmas...

Last year, I had the honor of designing and sourcing new Christmas decorations for the Four Season's Hotel & Residence, here in Hong Kong. Last night, before picking up a few Christmas gifts at IFC Mall, I decided to swing by the hotel for a few drinks (and free dim sum… !) at Blue Bar. I mainly wanted to see if they were using my decorations again this year, and

I can't recall the exact number of themes needed to decorate each of the public spaces throughout the hotel, including the residence lobby and apartments, but I think it was 8 or 863 or something like. But, of course, each one was a complete blast to develop. Of them, the tree in the Blue Bar was without doubt my favorite. What you don't see from the above story board used in the final presentation is I had about three times the amount of ornaments developed for the Blue Bar tree, than any other theme. Blue isn't a color I care to use for Christmas, but I LOVE THIS TREE.

Sorry the pictures are so dark.

It's a bar. And, well… it's a bar.

The color inspiration came from this amazing glass block column in the middle of the bar.

Here's a little look at the huge lobby tree.

From this little story board and sample presentation…

Came this…

Merry Christmas!

Sunday, December 15, 2013

Ribbons and Bows 101

As I mentioned in my post regarding Nutcrackers, when I visit a factory and learn how something is made, I'm always surprised at how much of the process is executed by hand. A few years ago, when I visited my first ribbon and bow factory, I once again was amazed at how important hand work is to the process. Something as inexpensive as a .99 cent bow, is assembled and packaged by hand. In addition to Christmas trees and nutcrackers, today I thought I'd share how ribbons and bows make their way to your packages… just in time for Christmas!

Ribbons and bows are usually made of polypropylene (PP), which can be produced into any color or finish. The below images all consist of either mirrored metallic or iridescent laminated polypropylene, which I pronounce shinny and super shinny.

Above, from top to bottom and left to right, is the monster machine that magically produces rolls of PP. I didn't ask for details, I just took their word. As you can see by the Pantone board, the color options are endless. The rolls of PP are loaded onto cutting machines. These machines cut the large rolls into smaller widths. The workers take the smaller cut ribbons (which in this case had been spooled) and place them into the retailer's packaging. Once packaged, the workers then place the UPC sticker to the outside of package. Typically, every detail is directed by the buyer or product manager. In this case, we wanted the package to read from warm to cool, so the silver and white ribbons went in the package first (the bottom), followed by the gold and bronze ribbons last (top of package). If these instructions weren't provided, each worker would place the ribbons in different orders, which would cause each package to look different. UPC placement instructions are needed so store cashiers aren't searching all sides of a package, looking for the barcode. We also need to make sure the UPC label isn't covering important parts of the product.

The cut ribbon is also used to make bows. Below you can see the smaller cut ribbon being curled and cut into 6 inch lengths. The 6 inch strips are then counted, (in this case they used 6 ribbons for each bow) and staple by hand to a small square adhesive paper that will later secure the bow to your package.

The workers below are producing folded bows. Along with making sure the machines have adequate ribbon supply, as the machines finishes each bow, (one at a time) the worker removes the bow and tosses it into one of those boxes. Once the boxes are filled, they are taken to a table of workers for packaging and labeling.

These workers are folding sheets of tissue paper and placing into the retailers packaging.

Below is matte finished polypropylene being twisted. This machine feeds a 2.5 inch strip of PP and slowly spins the PP into a tightly twisted ribbon called Raffia.

And once again, here's a group picture of the factory's owners and management, along with my team as we head back into our home away from home… the VAN!

So, there you have it, Ribbons and Bows 101. I remember when I first learned workers stapled the curled ribbons by hand, or when I saw workers folding tissue paper (both being products I have purchased as a consumer a thousand times), I couldn't believe an actual person completed those tasks. When I tour factories, I don't have many questions when standing before a machine, as I would much rather see humans work. I am fascinated at what is still produced by humans and to learn why. For a manufacturer, the less people needed the better. Machines are consistent and never require pay increases or holidays. But as a consumer, I still like knowing as I rip into a package, that someone, somewhere, made it.

Merry Christmas!

Friday, December 13, 2013

Nutcrackers 101

No matter what the product, when we hear the term "made by hand", or "handmade", or "handcrafted", we typically equate that to better value or high end products. But in most cases, handmade doesn't automatically mean expensive. Take these nutcrackers, they retail for US$9.99 and are 100% handcrafted.

I took these images a while back, as I conducted a factory quality inspection audit for a big box US retailer. And since it's Christmas and all, I thought I would share how Nutcrackers are made. The answer, very patiently! These talented individuals specialize in manufacturing handcrafted nutcrackers. Due to a late issued purchase order, they had less than one month to produce over 450,000 nutcrackers. What did you do last month?

Makes you think twice before complaining about how your job seems

so monotonous or tedious, right?

Each worker is responsible for one task, such as painting the arms, or adding sequins or painting accent trim. As I walked around the production line, it was clear this guy clearly was the envy of all other workers. He got to assemble all the parts together and the last person to touch the nutcracker before packaging and labeling.

I think I would go postal at about 9:32am, if I had to do this all day.

I accidentally distracted this lady why taping this video.

GRA's (Glitter Related Accidents) are no laughing matter.

Imagine being this guy and suddenly have an itch in your eye! Yikes!

The next time you look at a Nutcracker…

take a real look and remember, it was made by hand.

.JPG) |

| This is a group picture with the factory management and owners, as we were leaving the Nutcracker factory. They made my favorite green bean dish for lunch. Super nice people! |

Merry Christmas!

Tuesday, December 10, 2013

Orchids!

I wanted to spruce up the bathrooms for holiday guests, so I decided to head across Victoria Harbour to the flower market in Prince Edward. As usual, the flower market delivered. I found these (all four) for only US $24.00!!

Merry Christmas to ME!

Monday, December 9, 2013

How to make a Christmas Tree:

This is NOT a post on how to actually make your own Christmas tree. Sorry if your Google search brought you here by mistake. Maybe it's my fault for naming this post "how to make", rather than "how one is made". But not knowing exactly who will read this, I feel keeping the audience open is best. You may own a factory in China. How do I know these things?

I develop stuff. Lots of stuff. I'm currently working on a post that covers some of the products I design, develop and source. But because it's Christmas, and so many of you just finished pulling out your artificial trees (which are fare better for the environment than real trees). I thought I would show how they are made. Still interested? Being in product development, when I see something that catches my eye, my first thought is always, "how was it made?" The first time I visited a tree factory, I was amazed at the process. Even today, after years of being in this industry, I still believe the magic and wonder of a Christmas tree takes birth in the factory, from the moment the first pine needle is formed. [tissue please]

Most artificial Christmas trees are made from polyvinyl chloride (PVC) or polyethylene (PE). If you have an artificial tree, chances are it's made of PVC. Since the majority of PVC pine needle manufacturing is done with robotics and machines, trees made of PVC are the most affordable option in the market place today. Trees made of PE are made by taking live tree branches and creating molds, which are injected with PE. The end product looks and feels more realistic, but the production is mainly done by hand. Which means PE trees are the most expensive option on the market, but definitely worth it. Not only do they look better, they are better. PVC plastic contains high levels of lead, where PE plastic has very little. Oh my God are you bored yet? I'm still here [in my element]. Sorry about that.

PE production is kind of slow and boring (unlike this post, right…???), so I'm only going to show how PVC trees are made. In order to make the branches look realistic, the PVC is died into several shades of green and brown. The more shades, the more expensive. In this case, I used three shades of green and two shades of brown (for the wood branch detail), and two different widths. Here's a look at the machine.

Here's a video to further explain the process.

So there you have it. Once the pieces are cut, they are then attached by hand to tree branches. On this day, we were making Christmas wreaths, not a tree, but I think you get the idea.

Below you can see the branches being wrapped around a wire, then applied to a wire frame forming a 24" wreath.

Most artificial Christmas trees are made from polyvinyl chloride (PVC) or polyethylene (PE). If you have an artificial tree, chances are it's made of PVC. Since the majority of PVC pine needle manufacturing is done with robotics and machines, trees made of PVC are the most affordable option in the market place today. Trees made of PE are made by taking live tree branches and creating molds, which are injected with PE. The end product looks and feels more realistic, but the production is mainly done by hand. Which means PE trees are the most expensive option on the market, but definitely worth it. Not only do they look better, they are better. PVC plastic contains high levels of lead, where PE plastic has very little. Oh my God are you bored yet? I'm still here [in my element]. Sorry about that.

PE production is kind of slow and boring (unlike this post, right…???), so I'm only going to show how PVC trees are made. In order to make the branches look realistic, the PVC is died into several shades of green and brown. The more shades, the more expensive. In this case, I used three shades of green and two shades of brown (for the wood branch detail), and two different widths. Here's a look at the machine.

Here's a look at the different colors and widths of the PVC strips. [side note: In addition to this matte finish, you can use polished PVC (in any color) to create a tinsel look. See end of post for pictures.]

Left to Right: All the strips come together, stacked and a wire is added. If you look closely, you can see the wire indention on the right side, but not on the left.

Amazing, right??

Left to Right: The strips are then cut perpendicular to the wire, creating the pine needles.

The machine then spins the stacked cut PVC, which secures it to the wire.

High pressure air blows and fluffs the needles into a realistic look.

And there you go, Magic and Wonder!

Here's a video to further explain the process.

The 20 foot strips are then cut into 4 to 6 inch strips that will later be used to form branches.

[BTW in case you're wondering, yes, the boy in this video is under legal age. School was out the week I visited this factory and I was told this boy wanted to help and be with his parents. In my opinion, those skilled muscles weren't formed in ONE WEEK! After a very long dispute, this boy was pulled from the production line. At least for the duration of my visit.]

So there you have it. Once the pieces are cut, they are then attached by hand to tree branches. On this day, we were making Christmas wreaths, not a tree, but I think you get the idea.

Below you can see the branches being wrapped around a wire, then applied to a wire frame forming a 24" wreath.

I left out a few steps, but I hope you get the general idea. If you don't, and you still aren't bored, let me know. I'd be happy to go into more detail. Promise.

If the forest green pine isn't to your liking, the same process can be done with shinny polished PVC. Here I am in another factory making a collapsable tinsil Christmas tree.

Merry Christmas!

Sunday, December 1, 2013

It's Beginning to Sound A Lot Like Christmas!

Living in Hong Kong offers the freedom of not dealing with all the hassles of having a car. Driving in traffic, pumping gas, parking… I don't miss any of that! However, I do miss that time alone, as I'm never alone in this city. I also miss my Sirius stations and being able to put in a good Christmas CD and having that be my soundtrack to all my December running-arounds. So this year, after hours and hours spent on iTunes, as I walk from home to work and home to shop and from home to eat and, well, everywhere… I'll be listening to a playlist that is nothing short of complete awesomeness. If I may say so myself.

If you're looking for an eclectic mix of classics, country and contemporary tunes then consider this my gift to you! Merry Christmas!

If you're looking for an eclectic mix of classics, country and contemporary tunes then consider this my gift to you! Merry Christmas!

- Have Yourself a Merry Little Christmas by Michael Buble

- It Must Have Been the Mistletoe by Barbara Mandrell

- Rockin' Around the Christmas Tree by She & Him

- Home by Blake Shelton

- Christmas Means Love by Joan Osborne

- Blue Christmas by Elvis Presley

- Chestnuts Roasting On an Open Fire by Ray Charles

- Silent Night by Mariah Carey

- O Holy Night by Aaron Neville

- Have Yourself a Merry Little Christmas by She & Him

- White Christmas by Diana Krall

- Silent Night by Mary J Blige and Marc Anthony

- Happy Christmas (War is Over) by John Lennon

- Sleigh Ride by She & Him

- Christmas Without You by One Republic

- Country Christmas by Loretta Lynn

- The Magic of Christmas Day by Celine Dion

- Hallelujah by Chris Mann

- Have Yourself a Merry Little Christmas by Ingrid Michaelson

- Blue Christmas by Andrea Bocelli and Reba McEntire

- Rudolph the Red Nose Reindeer by Jack Johnson

- Someday At Christmas by Stevie Wonder

- Auld Lang Syne by Andrew Bird

- I'll Be Home For Christmas by Chris Mann

- Christmas by Lady Antebellum

- The Christmas Waltz by She & Him

- O Holy Night by Martina McBride

- I Saw Mommy Kissing Santa Claus by Jimmy Boyd

- When You Wish Upon a Star by Mary J. Blige, Barbra Streisand & Chris Botti

- The Christmas Song by She & Him

And it goes without saying, Mariah's Merry Christmas album [Geniuses Book of World Records Note: Best Selling Christmas Album of All Time] is, well, the best Christmas album of all times!

Merry Christmas!

Subscribe to:

Comments (Atom)